Thanks to its unique parametric software and its new “modular” ring clamping system, GSKET has developed this new fast and flexible to use machine model. Moreover, the modular jaws drastically reduce the cost of tools for each gasket. Perfect for small batch production as well as high loads, the operators will love how easy and efficient it is in everyday usage.

ASK GSKET > PRINT >

Ideal to groove big gaskets. Anyone without expertise and without a constant use of the machine can obtain repeatability and high-quality gaskets.

ASK GSKET > PRINT >

This grooving machine comes with a great dimensional range, ease of use and a unique patented GSKET technology for the specific purpose of grooving inner rings and outer rings for spiral wound gaskets. The technology on this machine will pave the way for future MKG models.

ASK GSKET > PRINT >

Ideal for large-scale production.

Fully automatic loading and unloading from ½” to 8” for SWG Inner rings and from ½” to 5” for Camprofiles/SWG outer rings. Manual loading and unloading is available from ½ ” up to 500mm O.D. As an optional, the “modular” jaws drastically reduce the cost of tools for each gasket.

The only machine of this kind on the market, tailored for the specific purpose of grooving inner rings and outer rings for spiral wound gaskets. With a cycle time of about 3 seconds this machine is perfect for big batches and very high production.

ASK GSKET > PRINT >

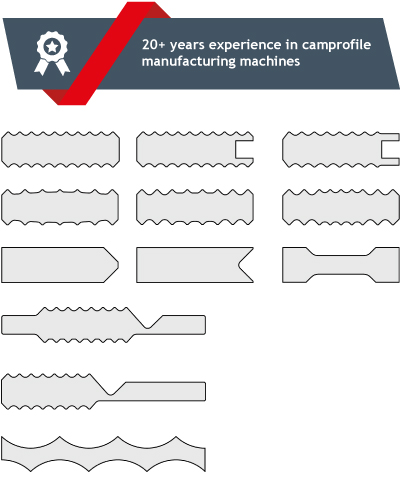

Working with the most renown and demanding producers made GSKET constantly pursue perfection in every aspect of its equipment. GSKET machines are always updated to the strict safety regulations in Europe and every year we develop new important features to help gasket producers to fully satisfy their costumers’ needs. Choosing a GSKET machine, you can be certain that its precision, speed, safety and consistency will always be at the top. From 2017 is available a new software with axis circular interpolation that allows to “draw” any special profile you want to achieve along with the most common profiles that have always been ready for use. We are fully dedicated to the continuous improvement of our projects; It is in this view that we have made ours A. Camus motto: “Real generosity towards the future lies in giving all to the present.”

PRINT >